We specialize in designing and manufacturing custom skid systems, including modular process skids and pump skid packages. Our skid solutions are tailored to meet your specific process requirements, offering increased efficiency, reduced downtime, and improved safety for your operations.

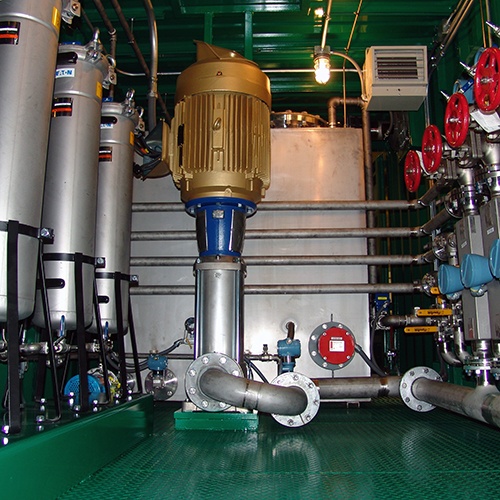

They provide constant water/glycol pressure with variable flow demand. The system utilizes ITT PumpSmart control in conjunction with an ABB paperless recorder. System pressure, water consumption, and power consumption are recorded and displayed in real-time and totalized for download.

Energy conservation is a key component of the system's design.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

An Automatic Filtering Skid System is a pre-assembled, skid-mounted filtration unit that automatically removes suspended solids and particulates from liquids using self-cleaning or automated filter mechanisms. These systems use sensors, timers, pressure differential triggers and can include PLC’s to initiate the filtration process, cleaning cycle, or indicate a media change. It can include self-cleaning filters, automated and manual valves, pumps (if needed), controls, and instrumentation, all pre-piped and pre-wired for easy installation and operation.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

A chemical metering system accurately feeds chemicals into a process. It typically consists of pump(s), flowmeters(s), valves, control panel, and any other necessary instrumentation depending on the application. A chemical metering system provides accurate dosing of chemicals into a process, ensuring a product that meets specifications.

A chemical metering system, also known as a chemical dosing system or a chemical feed system, is commonly used in the pulp and paper industry and wastewater applications, but chemical metering systems can be useful and many other industries as well.

Modular process skids offer a flexible and efficient solution for integrating chemical metering systems into industrial processes. These pre-engineered and pre-fabricated skid units are designed to house all the necessary components, including pumps, valves, instrumentation, and control systems, in a compact and self-contained package.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 85 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

A tank cleaning skid is a self-contained unit designed to efficiently clean various types of tanks, including storage tanks, process tanks, and transportation tanks. This is a crucial piece of equipment in industries like food and beverage, pharmaceutical, chemical, and oil and gas.

The Tank Cleaning System removes contaminants that accumulate during the manufacture of enclosed tanks. It is a self-contained skid mounted tank cleaning system that automatically cleans and validates to complete the tank manufacturing process.

After manufacture, the tanks are located adjacent to the skid. High pressure nozzles mounted on booms are attached to the tanks using a cleaning chemical for the wash cycle. Once the tank is washed, cleanliness is validated using cleaning chemical and filter media. The tank is then dried and fogged with a rust preventative.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

Container Flushing Systems are perfect for shipbuilders looking to automate manual or time consuming processes. It removes small and large metal, plastic and other debris along with liquids that accumulate during the construction phase of fluid support systems used on ships.

It consists of oil and water flushing skid systems designed for both new construction and retrofits.

The systems are housed in a container that can be located on or adjacent to a ship. Once electric power is provided to the main control panel and the piping is attached to the system, the system is filled with the appropriate liquid and the flushing process can begin. The systems are portable and customized to handle the variety of fluid support systems used on ships.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

Facility managers looking to streamline a mixing process by eliminating a mix tank, save floor space, and reduce the time required to make down a specified product that contains multiple ingredients, will appreciate the small footprint and big capabilities of fully automated inline blending systems.

An inline blending system, also known as a chemical mixing system, chemical addition system, or static mixing system depending on the industry or application, is a packaged system typically designed to mix multiple ingredients into solution at precise rates resulting in a homogenous product with the desired concentrations of each ingredient.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

A dry polymer makedown system efficiently converts dry polymer powder into precise solutions, reducing costs and waste in industries like water treatment, mining, oil and gas, and paper manufacturing. By taking control of the polymer makedown process, businesses can achieve precise dosing, minimized waste, automated systems for consistent results, and reduced chemical usage.

See the tabs below or visit our Makedown Skids page for more information. If your business is in need of a makedown or similar skid system, request a consultation today!

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

A Starch Cooker Skid System is a pre-engineered, packaged system designed to automatically cook raw or pregelatinized starch into a usable adhesive solution for industrial processes, typically using precise water, steam, and agitation control to achieve the desired viscosity and consistency. It's mounted on a compact skid for easy integration, startup, and consistent batch or continuous operation.

They offer a range of process and instrumentation options tailored to plant needs, including run tanks for fresh on-demand starch, additional dry make-down systems or super sack unloaders, and heating skids or boilers to minimize gelatinization time.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

A Glue Dilution skid system is a pre-engineered, automated system designed to accurately dilute concentrated glue or adhesive to the correct process-ready concentration, then deliver it consistently to the point of use in production lines. The system typically includes precision metering pumps, water addition, mixing, agitation, controls, and instrumentation mounted on a compact skid for plug-and-play installation.

Precision dilution is essential for consistent product quality. Over- or under-dilution can cause bonding issues, production delays, and product rework. Automated skids solve these problems by delivering accurate, repeatable results every time.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

A Tote Tipper (also known as tote dumpers, tote tilters, IBC tippers, tote unloaders, or bulk decanting systems) Skid System is an engineered, modular unit designed to safely and efficiently empty materials from IBC totes, drums, or containers. These systems use a pneumatic or mechanical tipping frame mounted on a steel or stainless-steel skid, often paired with safety guarding, integrated controls, and optional components such as pumps, day tanks, agitators, and instrumentation.

By automating the tipping and discharge process, they eliminate the need for manual handling and ensure a steady, controlled flow of product into the next stage of production. Many systems incorporate a day tank so operators can swap out totes without shutting down equipment—keeping processes continuous and avoiding costly downtime. they improve safety, reduce waste, minimize labor, and provide a predictable, clean, and reliable material flow—bridging the gap between bulk inbound containers and continuous production.

We have years of experience building custom engineered skid system for a diverse portfolio of industries. We know a great system starts here, with a great process.

Crane Engineering has been a leading fluid handling equipment distributor for over 75 years. Companies turn to Crane time and time again for the distinct advantages we deliver to our customers every day.

At Crane Engineering, we've brought together the people, products, and experience to enhance your process. Leverage our abilities to make the Crane Advantage, your advantage.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.