Facility managers looking to improve operator safety and ergonomics and process or project engineers seeking accurate and consistent delivery of chemicals or ingredients appreciate the small footprint and big capabilities of fully automated makedown skid systems.

Dry chemical, polymer, and ingredient makedown skid systems are important pieces of equipment in manufacturing and industrial applications to support the delivery of target concentrations of additives to products or processes, with precision, at specific points in the production process.

Are you currently challenged with operator safety issues, high chemical and ingredient shipping costs, or variability in your ingredient concentration or rate of addition in the production line?

Or maybe your facility is space constrained in the chemical warehouse?

Makedown skid systems are designed to remedy many of the common challenges operations and product lines face in food and beverage, industrial, consumer product, wastewater, and municipal facilities.

Here are just some of the inherent benefits of adding a makedown skid system to your production line:

Do you have additional questions about the benefits of skid systems and how they can support your production line goals? Contact our team today or request a quote online to get the conversation started.

A makedown skid system designed to fit the specific needs and requirements of your production line can help save your business time and money while improving overall efficiency.

Here are some of the features and efficiencies that makedown skids offer:

From streamlined operational safety to improved dosing accuracy, makedown skids are a valuable asset to any production line. But which industries benefit most from makedown skid systems?

There are several key industries which benefit from the use of makedown skid systems.

Some common examples of makedown skid system industry applications include ingredient makedown, chemical feed, dry chemical and polymer makedown skids.

Manufacturers around the world turn to Crane Engineering for our innovative skid system solutions custom designed to match the production requirements of each unique customer application.

We are fluid technology experts and system integrators with proven examples of system innovation. Crane Engineering offers customers exceptional service and product solutions, including:

Our Wisconsin-based team manages service and repair across North America, and is laser-focused on providing an unmatched customer experience, and responding promptly to questions and requests. Trust our team to do the same for you.

Crane Engineering builds each skid system to meet the unique needs and requirements of each customer.

We work with each client to discuss several key factors, including:

Crane Engineering has been serving customers for more than 80 years and is Wisconsin's largest distributor of industrial-grade pumps, valves, filters, wastewater treatment equipment, and other fluid processing technology.

With locations in Wisconsin, Michigan and Minnesota and offering many products nationwide, Crane Engineering has the expertise and experience to help you with your fluid processing needs. Contact our team today to learn how we can help your business grow.

What is a makedown skid system?

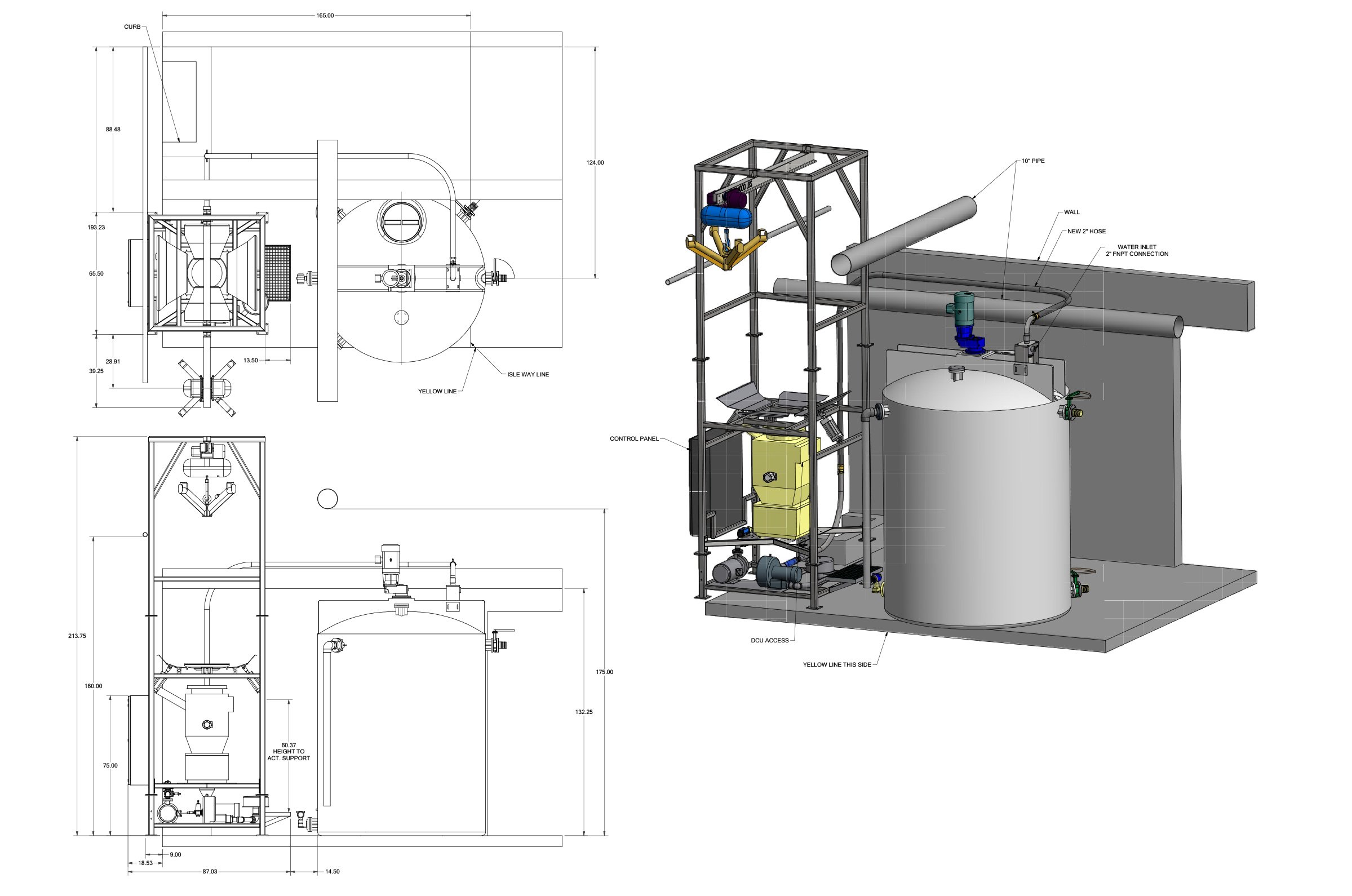

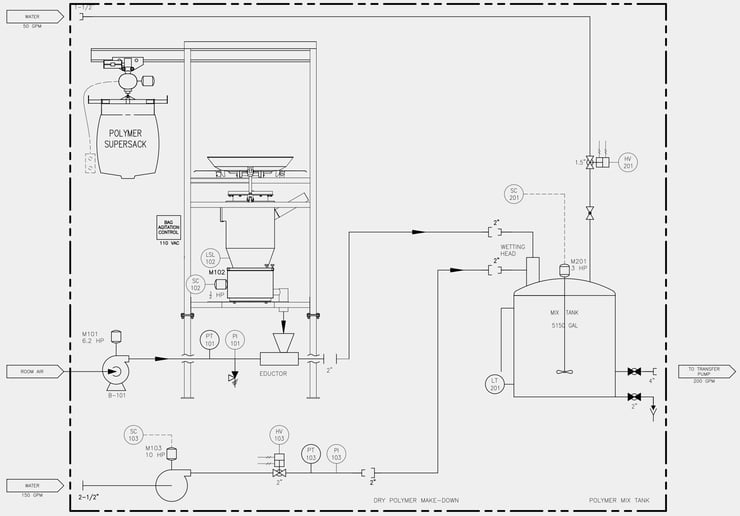

A makedown skid system is designed to take a dry material and blend it with water to get the right concentration. Different blending methods are used depending on the product. Blended chemicals or ingredients are then delivered to the process at the correct concentration and flow rate.

What is polymer makedown?

A polymer makedown skid is tasked with preparing and mixing polymer solutions utilizing low shear methods to insure that every particle is fully wetted.

Which industries typically use makedown skid systems?

Makedown skid systems are commonly used in the food and beverage industry, the pulp and paper industry, general industry, and in both industrial and municipal wastewater treatment applications.

Does Crane offer service support and spare parts for makedown skids?

Crane Engineering offers full makedown skid system service support, including recommendation of spare parts, skid repair and rebuilds and site startup and commissioning support. We’d be happy to help you with your service questions and requirements. Contact our team for more information.

What geographic area does Crane Engineering cover for makedown skid products and services?

Crane Engineering offers makedown skid products and services across North America.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.