Extend the life of your assets, and protect employees from dangerous slips, trips, and falls with a custom solution from Crane Engineering.

It's critical that surfaces in food and beverage facilities are easily cleaned, rust free, and won't harbor bacteria.

Typical solutions we provide include:

Chemical production can be corrosive and hard on equipment, tanks, and concrete floors. We provide services to keep corrosive chemicals from eating your assets.

Typical solutions include:

Age, environment, and chemicals can cause deterioration and corrosion in your plant. We provide services to restore concrete, tanks, and equipment to like new condition.

Typical solutions include:

We've worked within the pulp, paper and tissue industries since we opened for business in 1939. We know that age, environment, and chemicals cause serious deterioration and corrosion problems. Let us help you save the cost of replacement over restoration.

Typical solutions include:

Age, environment and chemicals cause serious deterioration and corrosion problems at wastewater treatment plants. We have an extensive portfolio of turnkey restorations provided to municipalities throughout the state of Wisconsin.

Typical solutions include:

Age and environment cause serious deterioration and corrosion problems. We have an extensive portfolio of turnkey restorations provided to schools and medical facilities throughout the state of Wisconsin.

Typical solutions include:

When installing new, or upgrading old areas of your facility, Crane Engineering has the expertise to help make it happen.

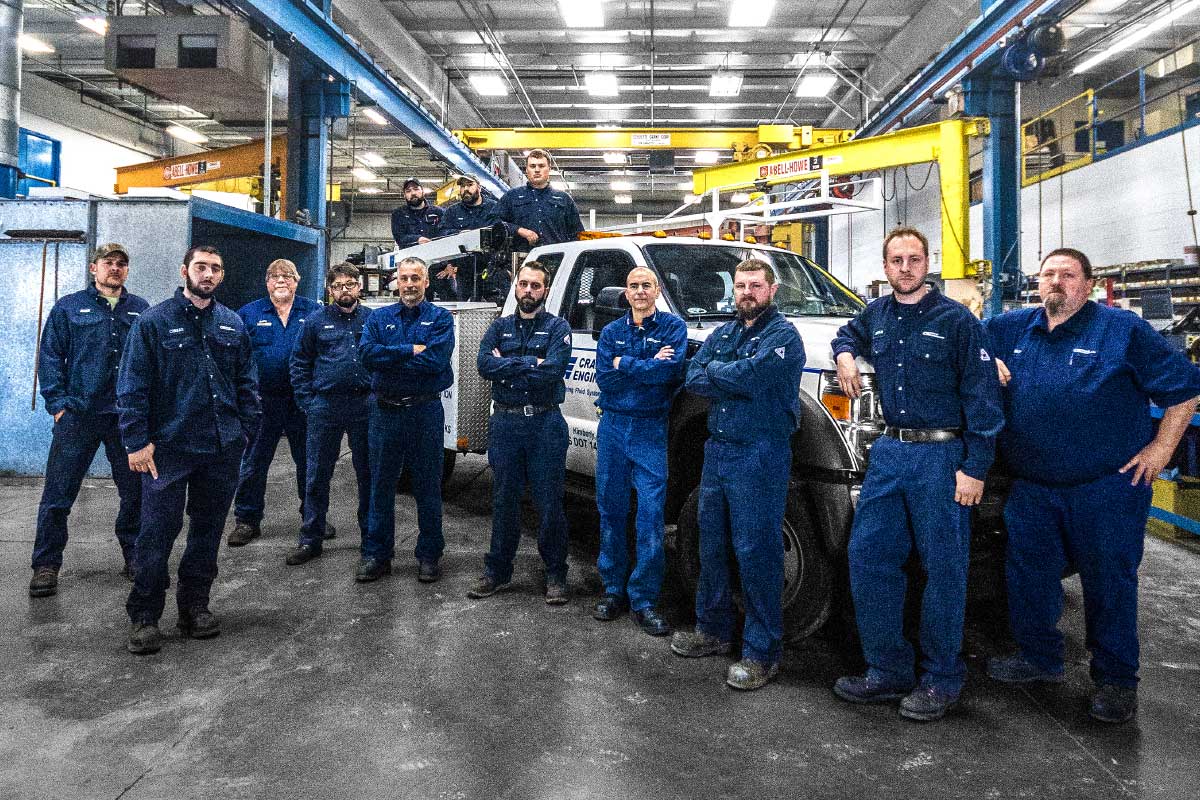

Our professional services free up time for you to work on other things, while we make sure repairs and turnkey installations are made to last.

Proper preparation and installation is critical to extending the life of your new coating.

The experience and know-how of Crane Engineering's qualified installation crews ensures they will select the right product for your unique environment, and install your new coating system properly, ensuring a long lasting product.

Settling or shrinkage of a concrete slab can cause cracking over the life of your concrete flooring. Our installation team properly repairs cracks and control joints, and also patches larger areas to help you get more life out of your concrete.

Does your floor drain properly? As part of your flooring project, Crane Engineering can pitch or level your floors to ensure that your process flow moves towards the drain instead of pooling in unwanted areas.

Take your work area one step closer to becoming lean with 5S color designation. Help your employees work smarter and safer by indicating dangerous areas, aisleways, and areas to keep clear for operational purposes.

Tanks are constantly exposed to harsh contents like wastewater and corrosive chemicals. The life expectancy of your tanks depends upon proper maintenance.

Crane Engineering provides a tank inspection service that will help you monitor the health of your structure, and make recommendations to prolong its life and minimize maintenance costs.

Insurance claims stemming from accidents are very expensive, not to mention the time and productivity loss from injured workers.

Consider installing non-skid flooring to help protect your workers from dangerous slips and falls.

Preparation is the most important step in the process. Depending upon the situation, shotblasting, sandblasting, diamond grinding, and scarifying may be used to completely remove deteriorated coatings and concrete, ensuring the best adherence possible.

Our flooring systems are designed to be abrasion resistant, thermal shock resistant, as well as chemical resistant. Talk to us about your situation and we will select a product or design a system for your specific environment.

A few mils to 3/8". We can apply thicker if grouting is required.

Of course we prefer to have all equipment out of the way when we work in order to get the most complete coverage, but we understand there are circumstances where this is not possible. Fortunately we can work around equipment if needed.

We work around your schedule, even if it means working weekends or overnight.

Most products are 100% solids, any odor created will dissipate with cure.

Established in 1937, Sika Corporation, based in Lyndhurst, NJ, is a leading supplier of specialty chemical products and industrial materials serving construction and industrial markets including transportation, marine, and automotive.

It is also the largest company in the Sika Group with more than 900 people in 7 manufacturing, 2 R&D facilities, and sales and marketing offices throughout the country.

Since 1969, Milwaukee-based Micor has been a leader in high performance coatings and epoxy grouts. Micor offers an extensive line of quality-tested polymer formulations for correctional and institutional facilities, food processing, pulp and paper and chemical resistant flooring applications.

Dex-O-Tex® products offer a full line of waterproof deck coverings, specialty fluid-applied floorings, coatings, and decorative finishes for commercial, industrial, and residential facilities. No matter how demanding your environment, Dex-O-Tex has a flooring or surfacing product designed to meet your needs.

Chances are, if you have a corrosion problem, Carboline has solved it. Carboline Company is a world leading supplier of corrosion resistant products specializing in high performance coatings, linings, and fireproofing. Carboline consistently leads the industry in:

Strongwell has been pultruding fiber reinforced polymer composite structural products since 1956.

Today, with more than 66 pultrusion machines and 647,000 square feet of manufacturing space in three plant locations, Strongwell has unequaled capacity, versatility and flexibility to meet the needs of its customers and allied partners.

All Strongwell pultruded products are made in the USA.

Established in 1937, Sika Corporation, based in Lyndhurst, NJ, is a leading supplier of specialty chemical products and industrial materials serving construction and industrial markets including transportation, marine, and automotive.

It is also the largest company in the Sika Group with more than 900 people in 7 manufacturing, 2 R&D facilities, and sales and marketing offices throughout the country.

Established in 1976, Plas-Tanks has become one of the largest and most modern manufacturers of reinforced plastic products in the industry. Plas-Tanks has made a strong commitment to quality through our ISO-9001 certified quality management system.

Their 35+ years of experience has been supplying quality equipment to various industries around the world, including:

Enduro is a leader in innovative, engineered fiberglass products and systems. Enduro manufactures a number of FRP (GRP) products including roofing & siding panels, ladder tray for cable management, tank cover systems, baffle & partition walls for water & wastewater treatment, and FRP pipe & vessels.

Linabond® Co-Liners™ provide the highest degree of wastewater H2S corrosion protection available, for both new construction and rehabilitation of existing wastewater structures which have been damaged or destroyed by hydrogen sulfide corrosion. They are a sandwich composite approach which combines the highest fastening strength of any wastewater PVC liner in the world, with the backup protection necessary to keep the wastewater PVC liner a permanent part of the structure.

Wastewater PVC liners have been recognized for many years as the only way to ensure an impermeable membrane for wastewater structures. Linabond® Co-Liners™ are the ultimate wastewater PVC liners due to the fact that they have the highest fastening strength of any wastewater PVC liner in the world, as well as backup protection in the event of a puncture.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.