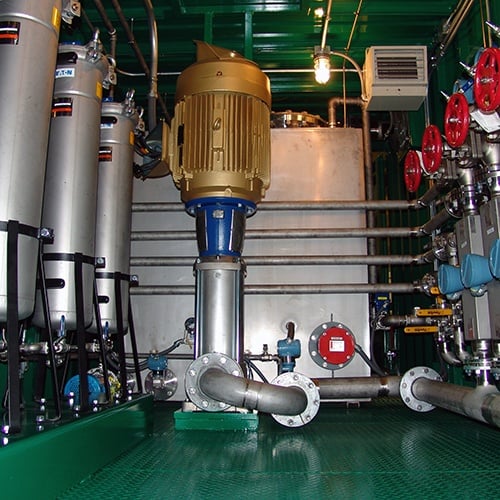

The TurboFlush is perfect for shipbuilders looking to automate manual or time-consuming processes. It removes small and large metal, plastic, and other debris along with liquids that accumulate during the construction phase of fluid support systems used on ships.

The TurboFlush consists of oil and water flushing skid systems designed for both new construction and retrofits.

The systems are housed in a container that can be located on or adjacent to a ship. Once electric power is provided to the main control panel and the piping is attached to the system, the system is filled with the appropriate liquid and the flushing process can begin. The systems are portable and customized to handle the variety of fluid support systems used on ships.

We have years of experience building custom-engineered skid systems for a diverse portfolio of industries. We know a great system starts here, with a great process.

Manufacturers around the world turn to us for the innovative skidded solutions and distinct advantages we offer every day.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.