The Bright Technologies Belt Filter Press is a state-of-the-art sludge dewatering solution that incorporates three US Patents and innovative features for high performance in a compact and high-value package. Designed with long-term value and ease of operation in mind, this belt filter press features a stainless steel frame and roller construction as standard, along with an Allen Bradley touch screen and PLC for seamless integration and unattended operation.

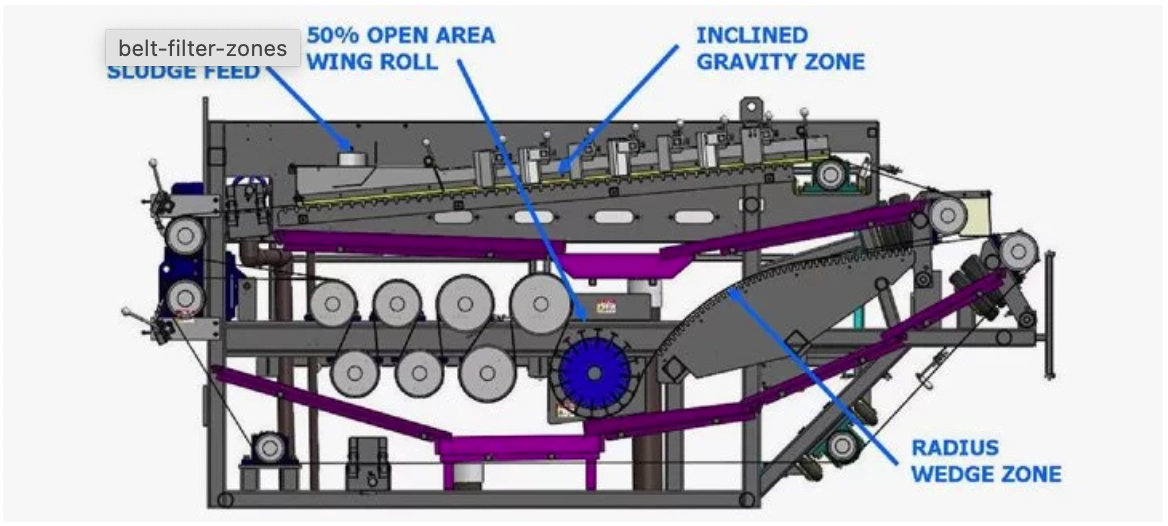

With superior design elements such as an inclined gravity zone, patented radius wedge zone, and high-efficiency pressure/shear zone, the Bright Technologies Belt Filter Press outperforms competing products based on older, inferior designs. The result is exceptional dewatering capabilities across a wide range of municipal, industrial, and agricultural applications.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.