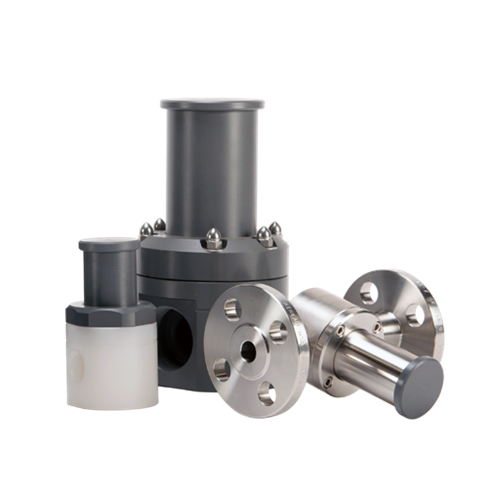

Blacoh SENTINEL™ Back Pressure Valves are essential accessories for optimizing the performance and reliability of your pumping system. Also known as loading valves or anti-siphon valves, these precision-engineered components apply continuous back pressure to the pump discharge, shielding it from detrimental downstream pressure fluctuations. The result is more consistent metering pump dosage rates, prevention of premature component wear, enhanced operational safety and efficiency, and seamless integration with multi-pump systems.

Blacoh's patented flow stabilization technology sets SENTINEL™ Back Pressure Valves apart from the competition. While typical back pressure valves tend to chatter loudly and wear out quickly due to rapid cycling between open and closed states, SENTINEL™ valves meter the flow to minimize upstream pressure drop. This innovative design eliminates chatter, extends service life, and ensures superior performance in demanding industrial environments. Made in the USA and built to last, SENTINEL™ Back Pressure Valves are your trusted solution for pump system optimization.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.