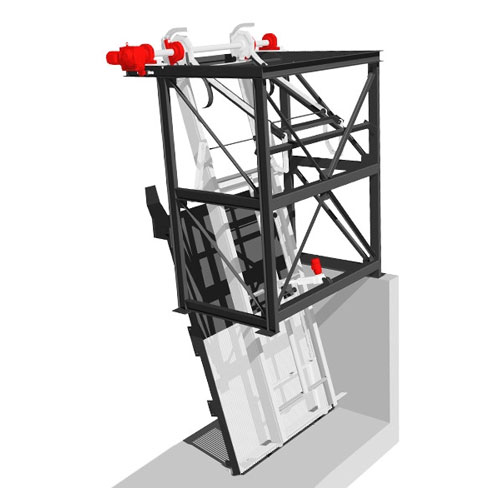

RAKEGUARDTM is a robust front raked bar screen which is well suited to raw sewage applications. The screen can be used at municipal and industrial waste water and process water screening where large concentrations of debris are expected.

With the RAKEGUARDTM waste water passes through the grid and captured screenings are removed by a chain operated rake that moves up the face of the grid. The screen comes with replaceable prongs which fits into the grid.

RAKEGUARDTM comes with a function that detects large objects and keeps the screen operational. The debris can be discharged into a shaftless screw conveyor system or launder trough. Two chains move the rake up and down and an overload sensor can be used to protect the mechanism during movements of the skip.

While the rake moves down, a control mechanism makes sure the guides are swung clear of any screenings. At the bottom the mechanism is operated, moving the guides back towards the screen grid, forcing the rake prongs into the spaces between the grid bars. This ensures positive engagement of the prongs with the grid. Once the rake hits a rigid obstruction during its upward movement, the power demand will increase which sends a signal to the actuator to withdraw the prongs from the grid.

When the resistance to movement of the rake is low the rake will continue, if this occurs before the prongs have cleared the obstruction, part of the debris will be cut away by the ends of the prongs. Any unusual obstruction as the prongs are pushed into the grid will signal the screen motor to lift the rake clear of the obstruction. The provided sensors come with adjustable time delays before cutting out on overload. If the screen hasn’t cleared the obstruction within the pre-set delay the screen cuts out. Once the RAKEGUARDTM screen operation is blocked, a mechanical overload protection interrupts the operation. The RAKEGUARDTM screen mechanism is set out of the waste water stream when it isn’t operational. All RAKEGUARDTM installations are customised to our client’s needs, and can be installed in new channels or retrofitted into existing channels.

Municipal screening, grit and biosolids handling equipment is Spirac's primary focus, however SPIRAC also offers screens, conveyors, dewaterers and washing solutions for industrial applications.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.