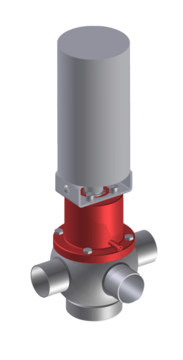

LIAG® free flow shutter valves are designed for maximum product safety in aseptic processes. The valves feature a unique leakage monitoring system for the dynamic O-ring seal, which identifies possible wearing defects and prevents contamination from the external environment. This special design ensures the highest level of product integrity and reliability in critical applications.

The leakage chamber can be configured as a steam barrier or equipped with a level of conductor control for monitoring via glycerine dilution. The pivoting axle is supported by a ball-bearing shaft, providing increased stability and reduced operating torque compared to standard shutter valves. This innovative design offers superior performance and ease of use in demanding process conditions.

For maxiumum product safety LIAG® free flow shutter valves are available with a leakage monitoring System of the only dynamic O-ring. This specific design identifies possibile wearing defects of the seal and prevents any contamination from the outside Environment.

The special designed leakage chamber can act as a steam barrier or offer monitoring via means of a level conductor control (dilution of glycerine).

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.