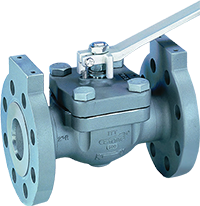

The Cam-Tite® Ball Valve stands out due to its unique beveled edge ball design. The spherical surface of the ball is cut away around the port edge, creating a bevel that energizes the seat when the valve is closed. This mechanical compression of both upstream and downstream seats ensures a tight and dependable seal despite line pressure. The valve's low operating torque reduces lateral loads on stem seals, extending seat life and eliminating the problem of "breakaway torque" during extended valve openings. With superior performance, positive material identification, and meticulous quality assurance, the Cam-Tite® Ball Valve remains a top choice for flow control solutions.

ITT Engineered Valves are essential equipment in industries ranging from mining to biopharmaceuticals, from nuclear operations to oil sands. With experience in valve development, design, manufacturing, installation and automation, product offerings include market-leading industrial knife-gate and hygienic diaphragm valves.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.