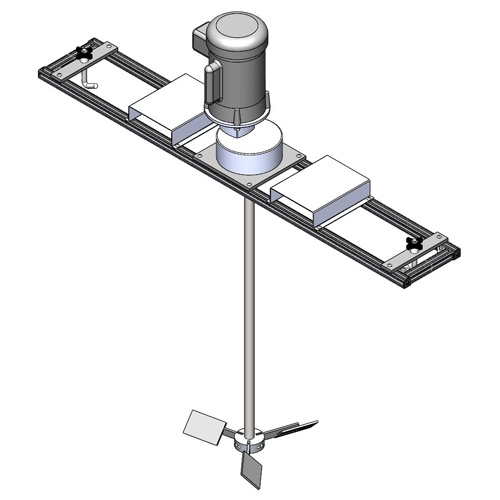

The Xtra-Flo Lite tote tank mixers are built for reliable, consistent mixing and blending in 275-gallon to 550-gallon IBC tote tanks. Engineered for durability, lightweight portability, and modular flexibility, these mixers accommodate wide viscosity ranges and fit almost all major IBC tank brands and sizes.

Premium metal alloy frames resist corrosion and provide support against bending and torsional stress. Simple design facilitates easy installation and removability while allowing a single unit to be used with multiple tank volumes. Configurations range from 1⁄2 HP direct drive propeller units for low viscosity mixing to 5 HP heavy-duty gear drives with large collapsible impellers for blending high viscosity fluids.

Since 1939, Cleveland Mixer has provided a complete line of industrial mixers and agitators for batch sizes from 5 gallons to 500,000 gallons. They serve the chemical processing, food processing, pharmaceutical and personal care industries in addition to customers in the water and waste treatment industry. With one of the most comprehensive liquid mixing product lines available, our mixers are used in everything from product development to full scale production systems.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.