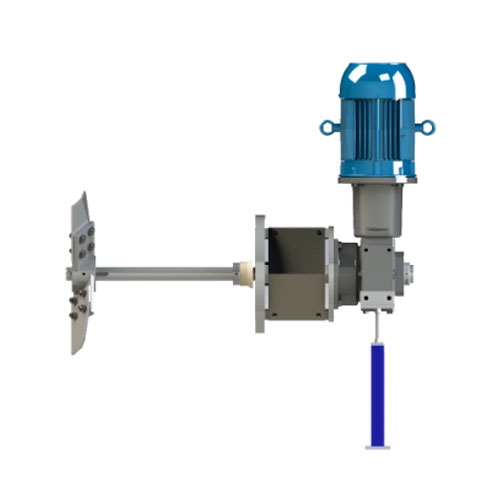

Side-entering mixers work efficiently where a tank is too large for convenient installation of a top-entering mixer, or where headroom is severely limited. Side entry mixers are less expensive than top entry mixers in large tank installations because the long shafts required by extremely tall tanks are eliminated. In the case of very large tanks, several smaller side entry mixers may be more efficient and economical than a single, larger unit. High performance shut-off valve with ancillary piping allows mixer to be maintained with the need to drain the tank. All models feature your choice of wetted end materials and the high efficiency XTF-3 hydrofoil impeller for maximum flow with minimal power consumption. Impellers are optimally selected per application. Shaft seal options include stuffing box with springloaded lubricator and single split mechanical seals—including bellows seals. Both include shut-off feature. An optimum mixing speed is achieved with one-stage worm gearing. This results in fewer bearings, seals and other spare parts. The involute helicoid gear form has manufacturing repeatability, eliminating the need for matched gear sets. This allows lower parts costs, spares requirements, and simplified repair procedures. Installs using pipe leg or tie rod outboard supports. Installation drawings are provided with each order. The SXT Series is ideal for process applications involving continuous blending, heat transfer, mass transfer, or solids suspension. It provides cost effective agitation of medium to low viscosity fluids in large storage tanks.

Since 1939, Cleveland Mixer has provided a complete line of industrial mixers and agitators for batch sizes from 5 gallons to 500,000 gallons. They serve the chemical processing, food processing, pharmaceutical and personal care industries in addition to customers in the water and waste treatment industry. With one of the most comprehensive liquid mixing product lines available, our mixers are used in everything from product development to full scale production systems.

Headquarters and Service Center

Located outside Green Bay, WI

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.