Improving efficiency with custom skid solutions.

Manufacturers around the world trust the Crane Engineering OptiFlow team to deliver innovative pump skid solutions. They turn to us for the distinct advantages we offer every day.

Your experience with our team is important. Our Wisconsin-based team is laser-focused on providing an unmatched customer experience, responding promptly to questions and requests. Trust our team to do the same for you.

GLOBAL CHEMICAL MANUFACTURER

Systems are designed using Autodesk® Inventor® to create a virtual model, allowing equipment interfaces and fits to be checked prior to assembly. Special attention on component location ensures proper functionality, maximum serviceability, and reduced operator risk.

Leveraging over 80 years of distribution experience and component know-how, we carefully size and select the right mix of equipment for optimal performance. After a bill of materials is developed, we work with our manufacturer partners to source at below market prices.

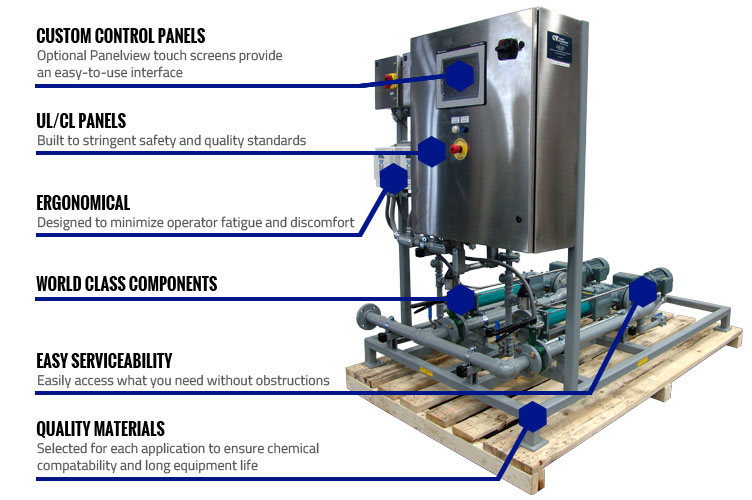

Experienced technicians and engineers collaborate to recommend potential improvements to increase serviceability or function. This yields superior workmanship and ensures all systems are built to the correct specifications. All control panels are built in our UL listed panel shop.

Your plant specifications determine the components our team selects, or we choose from leading technology providers like Allen Bradley, ABB, and Phoenix Contact. PLCs and Operator Interfaces are programmed with a focus on stable process control, ease of use, and reliability.

Before systems are shipped out to you, our engineers thoroughly inspect and test them. System trials are completed in-house in our test cell with the subject chemicals or water to ensure proper functionality.

Our clients visit us for final tests and inspections prior to shipping.

A comprehensive manual is created that includes a bill of materials, 3D mechanical and electrical drawings, P&IDs, equipment datasheets, and start-up/operating instructions. All are in an electronic format and utilize screenshots and photos to enhance key topics.

Proper installation and start-up are vital to the long-term operation of the system. Our experienced mechanical and/or controls personnel help install and start up your Optiflow™ skid systems upon request.

We fully back and support our systems by providing lifecycle services such as troubleshooting, maintenance, reconditioning, and asset tracking.

WET WIPE MANUFACTURER

With pump skid systems, there’s a lot on the line. We’re there for our systems the day they’re delivered, and we’ll continue to support them for years to come.

Headquarters and Service Center

707 Ford Street

Kimberly, WI 54136

920-733-4425

OptiFlow Design and Build Center

1002 Truman Street

Kimberly, WI 54136

920-733-4425

Burnsville Service Center

12265 Nicollet Avenue

Burnsville, MN 55337

952-444-1949

Grand Rapids Service Center

26489 Industrial Blvd

Cohasset, MN 55721

952-444-1949

© Copyright 2024. Crane Engineering. All Rights Reserved. Privacy Policy.